Testing

Supporting Environmental Test and Qualification

Thermal Unit Testing

Thermal testing of rugged electronics is a key diagnostic and verification tool for all electronics assembly use cases. It may be employed to verify design decisions, extract previously unknown material information, accelerate product ageing and much more. We can support you with support for all stages of these processes through design of the test to performing and delivering results.

- Component thermal performance test

- Module stress testing at elevated temperature

- Representative testing for all VITA 48.x cooling standards

- Wedgelock thermal performance testing

- Accelerated life testing

- Many other bespoke testing thermal options

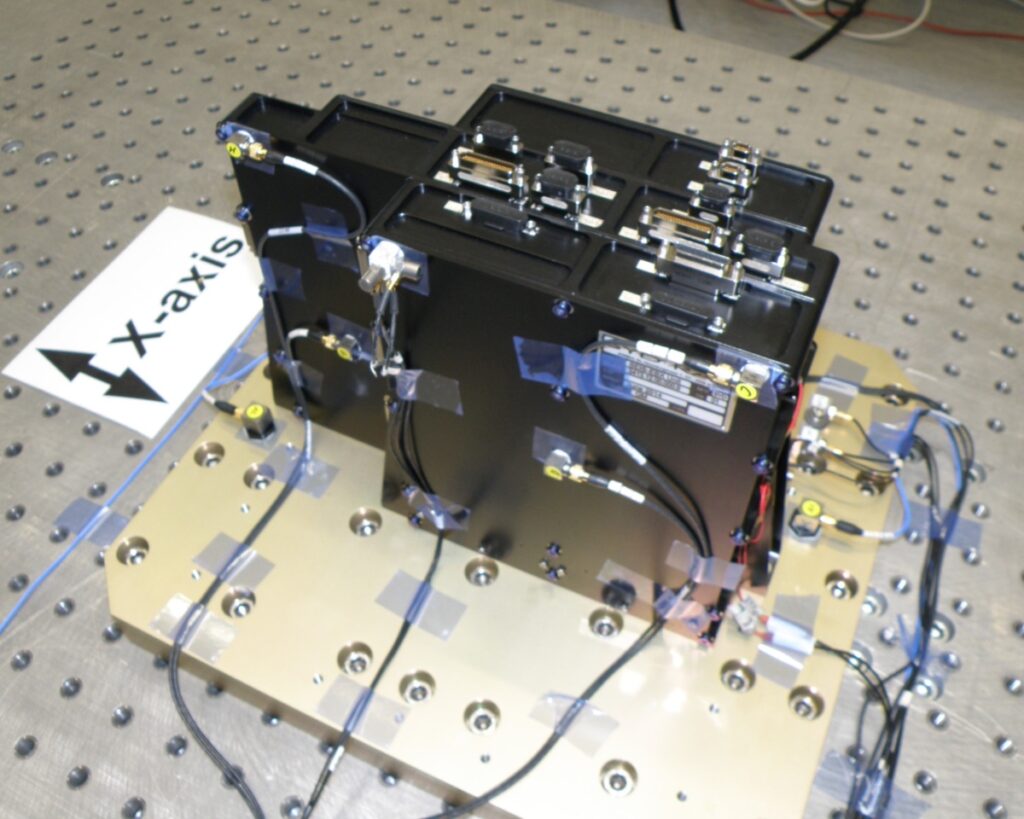

Shock + Vibration Testing

Rugged PCB’s and chassis must meet very stringent structural criteria for shock & vibration. While many critical design errors or coupling between devices can be identified through simulation, physical testing is still a requirement for comprehensive validation of a product.

To support qualification or certification of products, we provide a range of shock & vibration testing to suit your product survivability requirements.

Industry standard tests include:

- MIL-STD-810 methods 514.8 & 516.8

- MIL-S-901

- MIL-STD-167

- AECTP-400 methods 401, 403 & 417

- And any other standards that may be specific to your product

Test document writing

Having clear and defined test documentation is absolutely essential for maintaining product quality and for design development. Testing can be an expensive process and time wasted with inefficient processes, or unclear data capture, can result in fees and costly program delays.

We write defined documents for your bespoke internal processes, or clear process instructions which you can use to approach your chosen test houses for low hassle off-loading of test resource when required.